SAMUAL GROVES

A leading British cook and bakeware manufacturer

A Heritage in British Design

Global interest in British design and manufacturing has never been higher and Samuel Groves is building on this golden opportunity by continuing to invest in manufacturing equipment to produce the very best cook and bakeware at their manufacturing site in Birmingham.

Every range produced at our factory, we believe is the best you can buy, whether that’s our robust Tri Ply Stainless Steel or our Bakware Range.

Our foundation

Few suppliers of hospitality products go back as far as Samuel Groves. This venerable Birmingham-based manufacturer of kitchen equipment started in 1817, initially making brass candlesticks. By the 1870s, production had expanded to electroplated teapots and trays and it started to become a significant exporter in the 1910’s.

The company was started by Samuel Groves senior and was subsequently taken over by Samuel groves junior in 1866:

The big take-off into hospitality supply came during the Second World War when Samuel Groves won a major government contract to produce aluminium trays, with many other items for the Ministry of Works and the War Office soon being added. Including the Sirius incendiary bomb shield, utilising existing serving tray tooling.

The big take-off into hospitality supply came during the Second World War when Samuel Groves won a major government contract to produce aluminium trays, with many other items for the Ministry of Works and the War Office soon being added. Including the Sirius incendiary bomb shield, utilising existing serving tray tooling.

The introduction of the Mermaid Brand

This helped reinforce the foundations of the modern business, which gained a major boost from the introduction of the Mermaid brand at the beginning of the 1950s, Molly the Mermaid had first appeared in the 1920’s. The MD of the time saw a statue of a little mermaid in an antique shop and brought her back to Birmingham where she took up residence in the foyer of the factory. Her likeness has since proved an enduring logo.

Our manufacturing capabilities expand

The move into larger premises in Norton Street, Birmingham in 1965 enabled the company to expand its interests in cookware, bakeware, hollowware and utensils.Manufacturing operations were reinforced with the acquisition of the assets of G.W.Pearce & Co in 1995, which led to Samuel Groves becoming the original manufacturer of Agaluxe accessories for Aga Rayburn ovens and in 2002 with the acquisition of Buncher & Haseler, best known for its Longlife brand.

Our current leadership leads to a new chapter.

The purchase of Samuel Groves by U Group Ltd in 2014 was the beginning of a new chapter. Under the leadership of Lee McDonagh, who demands nothing but the best, the company continues to develop new products and utilise new materials, all of which are being manufactured at the U Group premises in Yardley Birmingham.

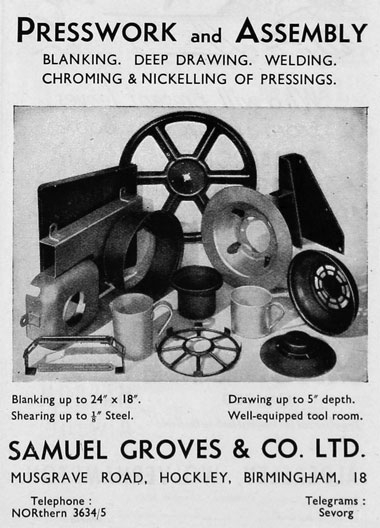

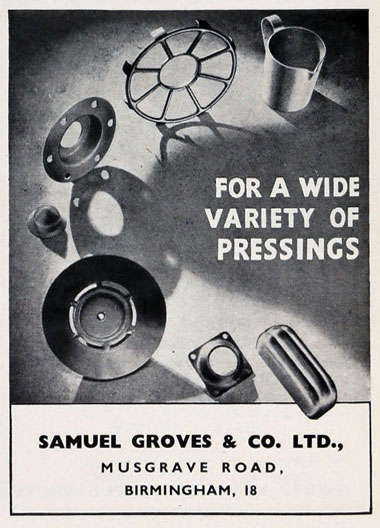

Samuel Groves encompasses all facets of manufacturing including Metal Cutting, Presswork, Metal Spinning, Welding, Fabrication and Injection Moulding. In addition, we are able to design and manufacture our own tooling in house. 2017 Also saw U Group purchase Utensa, to increase in bakeware manufacturing capacity.

Our UK expertise in developing bespoke collections

Our expertise in design, manufacturing and production can be utilised to develop bespoke cookware and bakeware using a variety of materials including aluminium, copper, stainless steel, mild steel and a range of plastics as well as numerous bonded materials. All developments are carried out in our factory and we welcome visits to discuss the best techniques and materials. We can then finish your product using a variety of finishing processes including Polishing, Sunraying, Hard or Soft Anodising, Powder Coating, Enamelling and Non-Stick Coating.

Our branded and bespoke products are designed for the 21st Century

Even though the market and indeed cooking practices have evolved over the years, Samuel Groves quality and processes have improved. We remain traditional manufacturers and every product we are proud to say are still hand-finished. We have been a manufacturer in Birmingham for close to 200 years, some of the skills that will be used in the factory today will have been used all throughout those 200 years.

Climate Care

Samuel Groves select ClimateCare to offset its carbon emissions with projects that improve lives and fight climate change.

As part of Samuel Groves’s approach to taking responsibility for their impact on the environment they have partnered with climate and sustainable development experts ClimateCare to offset the carbon emissions.

As well as taking actions to reduce its footprint through unavoidable emissions will be offset through projects including the multiple award-winning LifeStraw Carbon for Water Project, which delivers safe water to more than 4 million people in Kenya, generating significant carbon reductions and enhancing the health of local communities by reducing exposure to waterborne disease.

Other projects include the provision of clean cookstoves in Ghana, which significantly improve health while cutting emissions and reducing deforestation.

“We are delighted to work with ClimateCare who are experts in this field, with fifteen years’ experience running some of the most innovative and largest carbon offset programmes in the world. Working with them has helped us understand how we can integrate action to tackle climate change and improve people’s lives.”

Visit the Ronai Resource Centre for our full range of HoReCa brands.